Graduate Research

Additive manufacturing qualification

Computer vision metrology

Variance decomposition

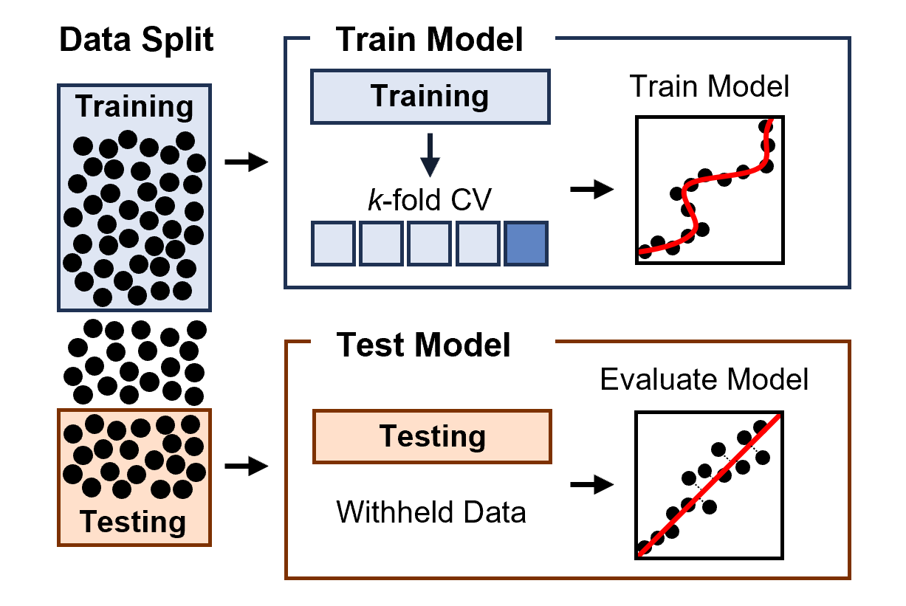

Machine learning predictions

Internal feature inspection

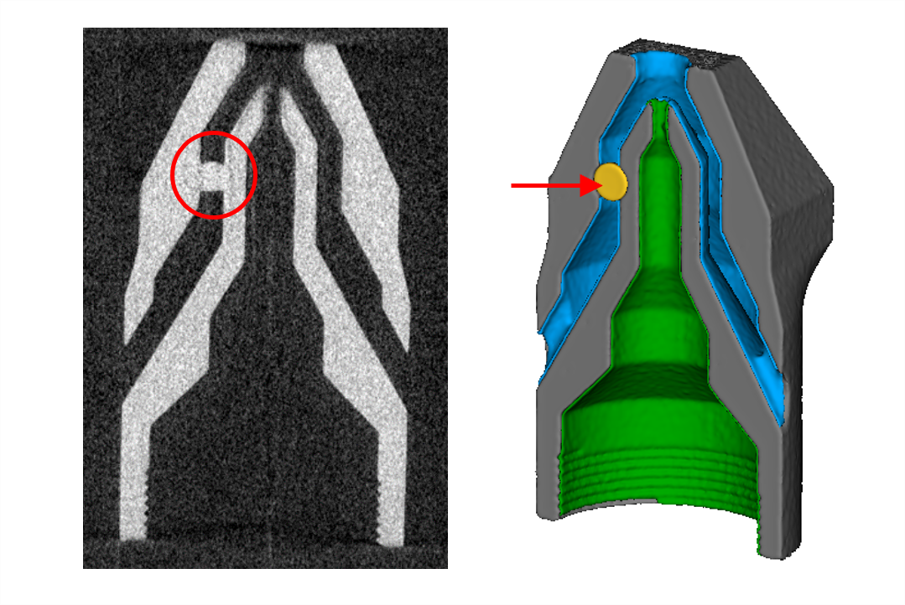

Defect detection

Additive Manufacturing Quality - King and Tawfick Labs

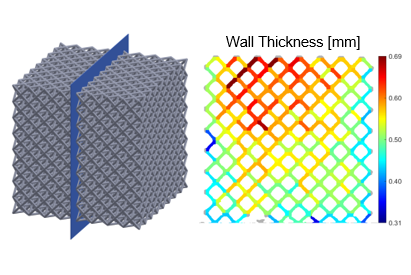

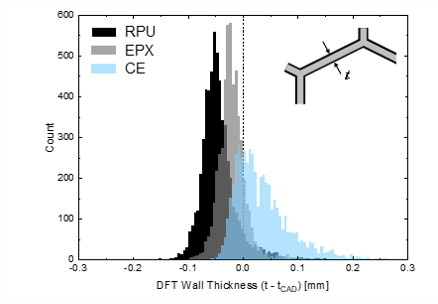

- Developed methods for scalable dimensional measurements and quality assessment of additively manufactured parts using computer vision, machine learning, and statistics

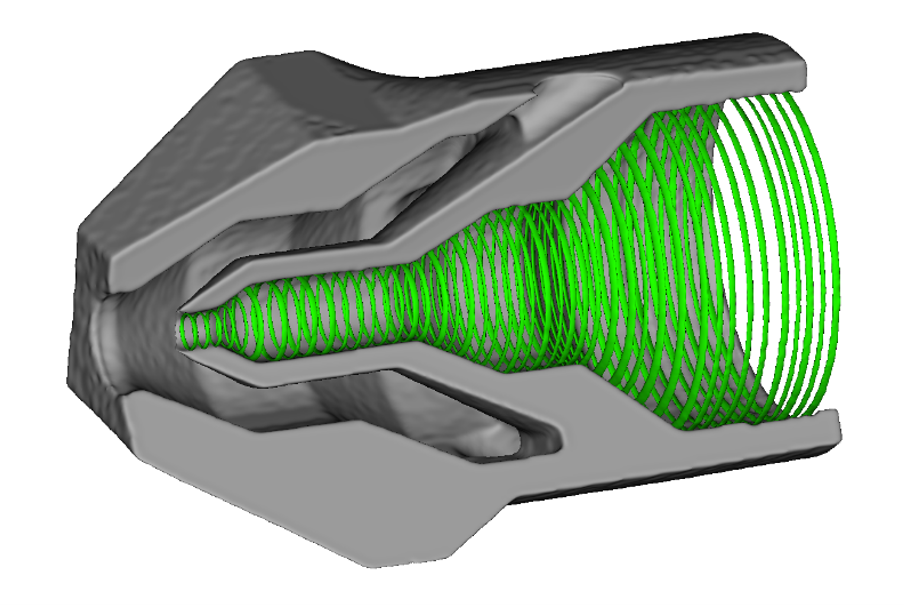

- Developed automated analysis frameworks for inspecting complex, 3D parts, especially those with internal features that are not measurable using traditional techniques

- Investigated additive manufacturing processes and materials using X-ray computed tomography (CT), variable focus microscopy (VFM), and optical images

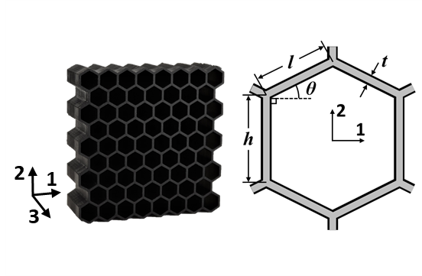

- Investigated mechanical properties and manufacturability of additively manufactured lattices

- Developed a Python package for computer vision metrology in manufacturing (open-source pip install release coming soon)

- Simulated lattice compression testing in ABAQUS to validate lattice material models and experimental results

Undergraduate Research

Biomedical Imaging - Barton Lab

- Designed mechanical system of micro-piezoelectric OCT/MPM endoscope for early-stage cancer detection

- Derived and experimentally verified resonant frequencies and shapes for a base excited, cantilevered beam with added tip mass

- Invented and manufactured custom surgical accessories for rodent analgesic delivery using AM and SolidWorks